When it comes to the maintenance of boilers, soot blowers are incredibly valuable machines. This equipment uses pressurized steam or air which is released through nozzle and effectively remove soot, slag from the boiler tubes. But what makes soot blowers cause the critical role for boilers work?

Boilers are used in power plants, heating systems as well as factories powering a vast variety of tools. Boilers need regular cleaning and maintenance to run at their best. An important part of this process is that the interior of a boiler stays clean and clear from any obstacles related to soot, as well as other materials, which can be accomplished with the assistance from soot blowers.

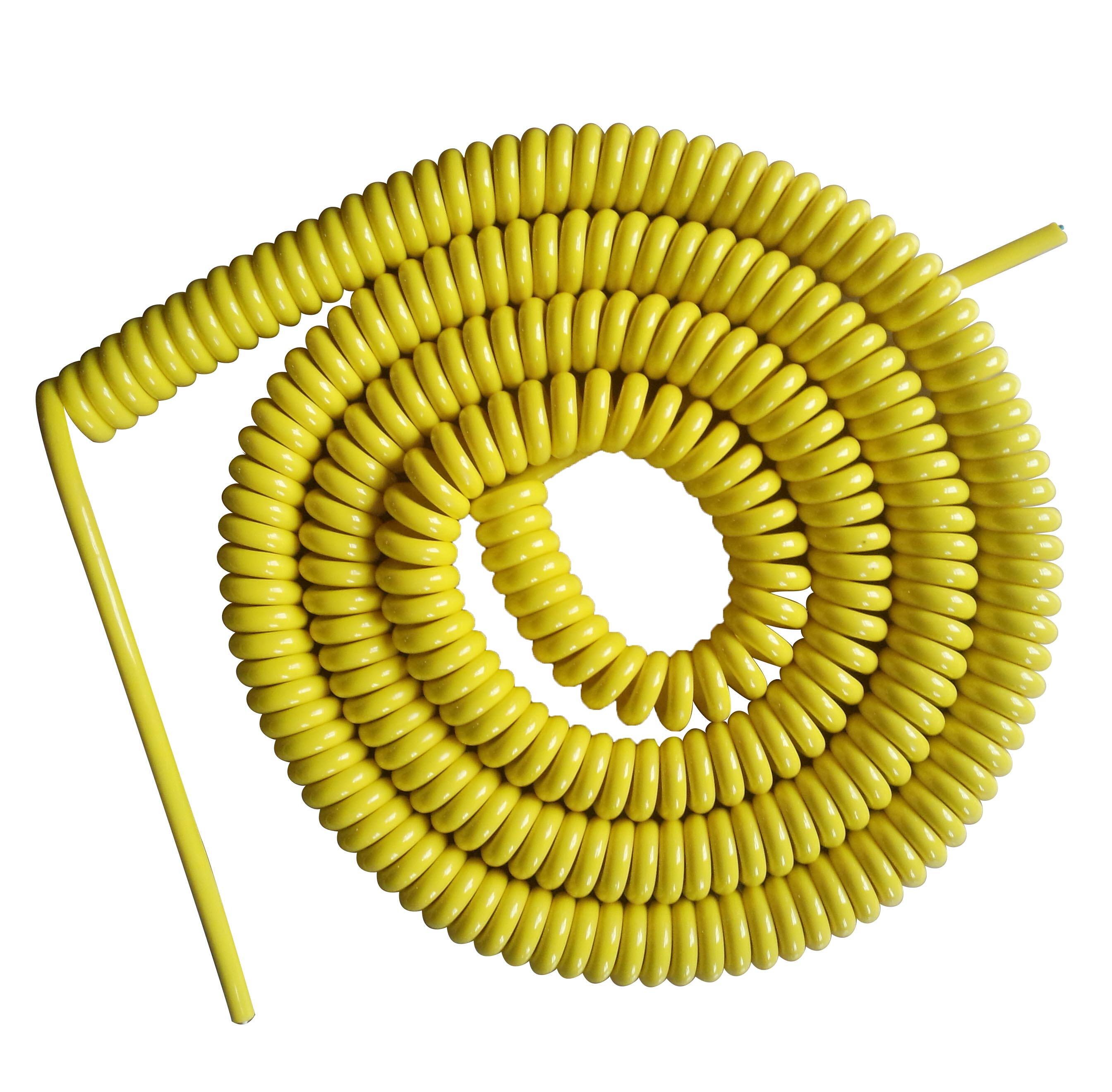

A dirty interior can reduce the performance of a boiler significantly. The build-up of ash and other deposit can result to reducing the efficiency, corrosion and also explosions. This is why the usage of soot blower spring cable solutions plays an essential role in having boilers performing at their best.

Businesses can prevent issues that would stop them form operating if they purchase a good soot blower spring cable. Making sure boilers run as reliably and efficiently as possible is key to keeping business moving - unexpected downtime or inefficiency in your boiler can lead a company's operations down.

Also, by using more robust spring cable material the life-span and shot effectiveness of soot blowers was being extended. Soot blowers suffer heavy usage and can be reduced in performance if they are not maintained correctly. So, durability in spring cable material is of utmost importance in sustaining this crucial machinery for a longer period.

Though, a company can save huge by using strong spring cable materials that are also durable and ensure it to be working appropriately as soot blowers. Soot blowers can last years when they are well maintained, reducing the costs associated with having to frequently replace or repair these units. This is an understandable move and very well worth the investment as it can save you a lot of money down the line.

In addition, a good quality soot blower spring cable acts perfectly to reduce downtime and increase productivity for business. Breakdowns in equipment cause operational disruption and severely affect profitability. By implementing the # materials, global businesses can keep their soot blowers from causing boiler efficiency problems and potential production disruptions due to broken parts.

Committed providing customers with an array Soot blower spring cable services We have a highly skilled after-sales department prep d assist customers with questions and address issues in the usage our products We'll fer quick and expert solutions problems with the product's quality or technical concerns We believe that a high-quality service after the sale can earn the trust customers and ensure satisfaction which is the most important element for the future growth a company

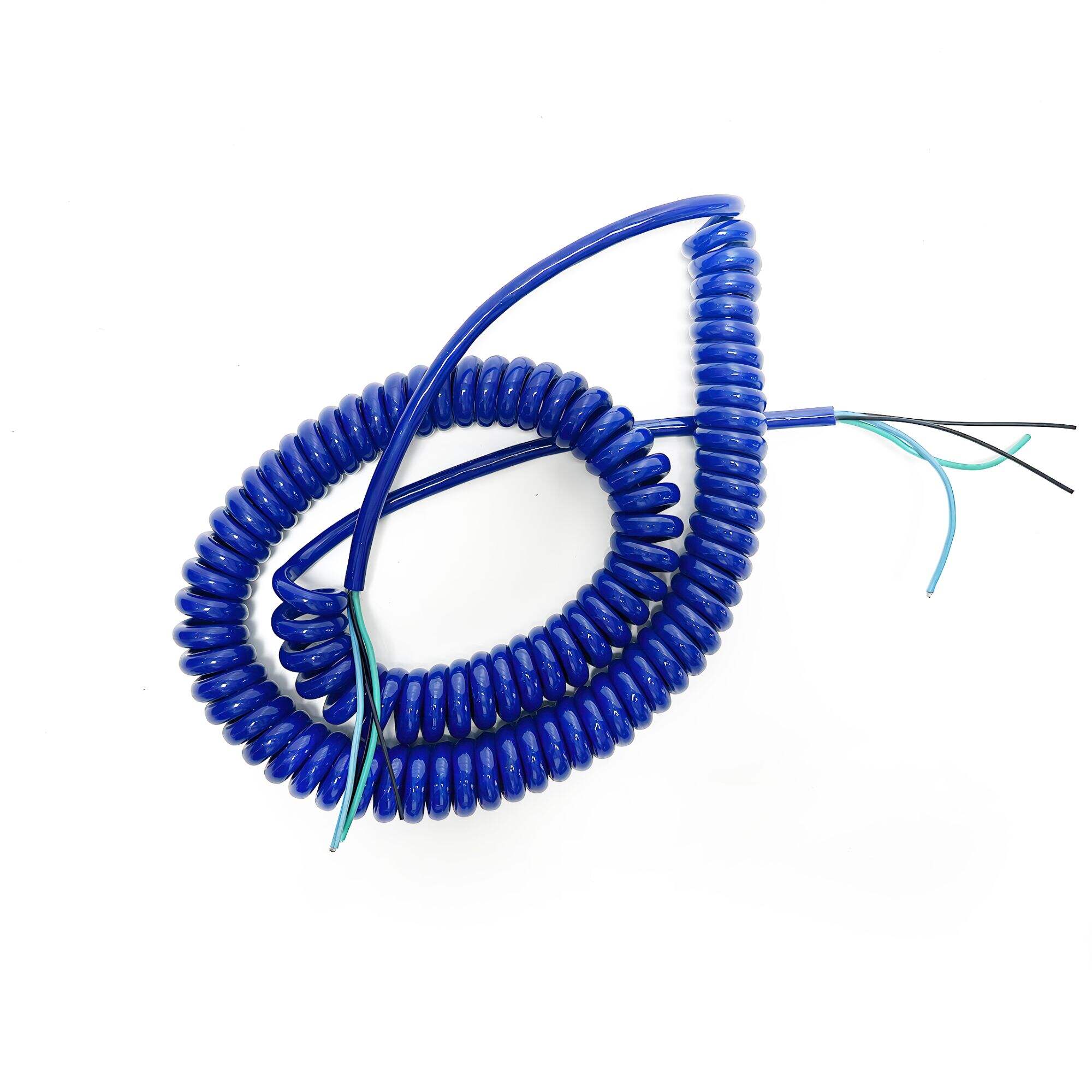

We are a specialist in spiral cables company that utilizes cutting-edge production technologies and strict quality control measures to ensure Soot blower spring cable durability, stability and dependability of spiral cables. While doing so we are committed to innovation and continuously develop new products that satisfy the demands of the market to meet the diversified requirements of customers. Our professional and enthusiastic support team is committed to providing outstanding pre-sales consult and after-sales support to our clients. We are a pioneer in spiral cable technology due to these advantages.

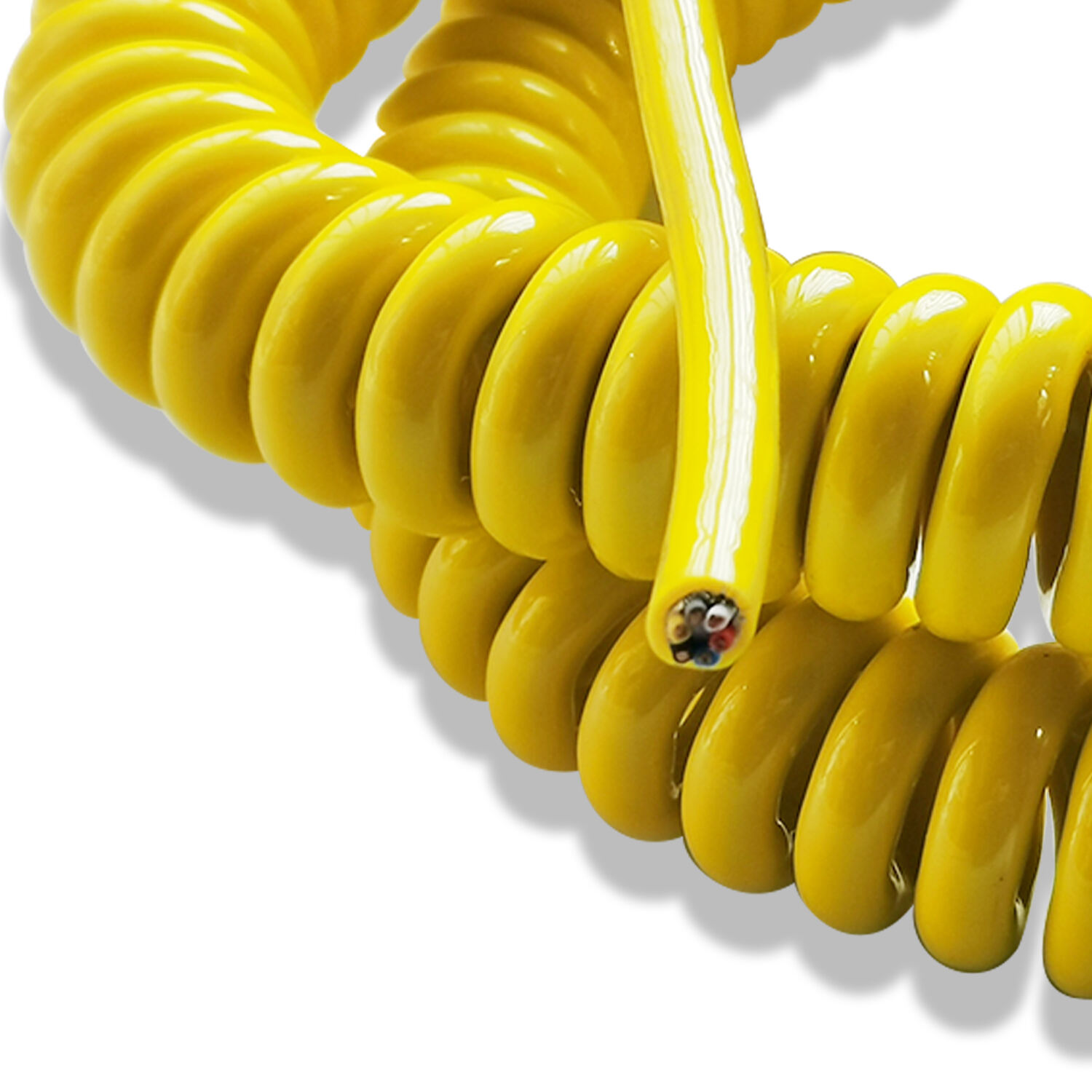

Soot blower spring cable cable compact structure strong tensile resistance cable extremely efficient excellent conductivity trailer line strong withstands tension which makes ideal many different environments gauges water level precise provide incredibly quick response times products well-known marketplace because fulfill needs variety customers

Our company is committed to providing top quality services and products Our research and design team consists of experts with a Soot blower spring cable of practical experience and deep expertise in the field They are constantly pushing technical boundaries to create spiral cable products with superior performance less defects and are more robust Our focus is on customer communication and collaboration We improve production procedures and designs of products on the basis of feedback and market demand in order to ensure that every product meets the needs of our clients